Your Reliable Manufacturing Partner

You are in front of the stage with great products while thingyfy is always your one stop manufacturing back up behind the scenes. Our capabilities cover design, analyzing design, prototyping and manufacturing with various processes including Rapid prototyping, 3D printing, vacuum casting, CNC machining, aluminum extrusion, rapid mold making, sheet metal fabrication, injection molding, die casting, PCB&PCBA production etc. Both low volume and mass production can be perfectly achieved with high quality and affordable manner.

Founded in 2016, thingyfy focus on integrating research and development, design, manufacturing services.

Thingyfy has been dedicated in manufacturing for many years owning professional and experienced engineering and management team.

Thingyfy has grown to an energetic high-tech company

Thingyfy's key employees have plenty of experience working in and serving for world fortune 500 companies

You are working with

● Experienced engineer team and professional pre/after sales service team.

● Advanced manufacturing and testing facility.

● Prompt delivery/fast response.

● Excellent cost control of logistics & duty.

Experienced in Design of industrial ,consumer parts and products

Manufacturing solution expert

Rapid response and fast delivery

Our manufacturing service empowers your innovation journey by providing expert Prototyping and Manufacturing Solutions. We use cutting-edge technologies for rapid prototyping,tooling, and low-volume manufacturing, turning your creative ideas into tangible, innovative products swiftly, accurately, and cost-effectively.

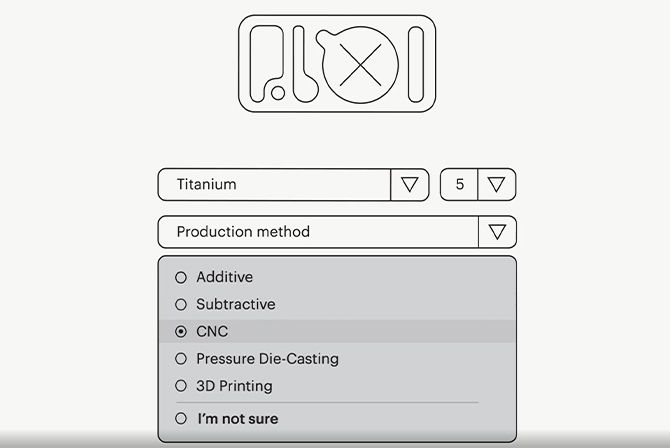

Upload Design

DFM Review

Confirm Quote

Production Starts

Metal stampings for applications in Consumer electronics, NEV, Industrial and more.

A Guide to Stereolithography (SLA) 3D Printing Materials

Jun. 23, 2025

Stereolithography (SLA) 3D printing is a widely used process that employs light-sensitive liquid resin to create high-precision parts. SLA is known for its ability to produce highly detailed and smooth parts, making it ideal for a variety of applications in industries like medical, automotive, consumer goods, and aerospace.

Guide to Liquid Silicone Rubber (LSR) Material

Jun. 13, 2025

Liquid Silicone Rubber (LSR) is a high-performance elastomer that is widely used in a variety of industries, from medical devices to automotive components. This versatile material is known for its durability, flexibility, and excellent resistance to heat, chemicals, and environmental factors.

Overmolding vs Insert Molding: Key Differences and Applications

Jun. 05, 2025

Overmolding and insert molding are often confused due to their similarities, as both processes fall under the category of injection molding. While they share certain characteristics, they have distinct differences that provide unique advantages in manufacturing. Understanding these differences is crucial for selecting the right process for your pro