Injection molding processing range

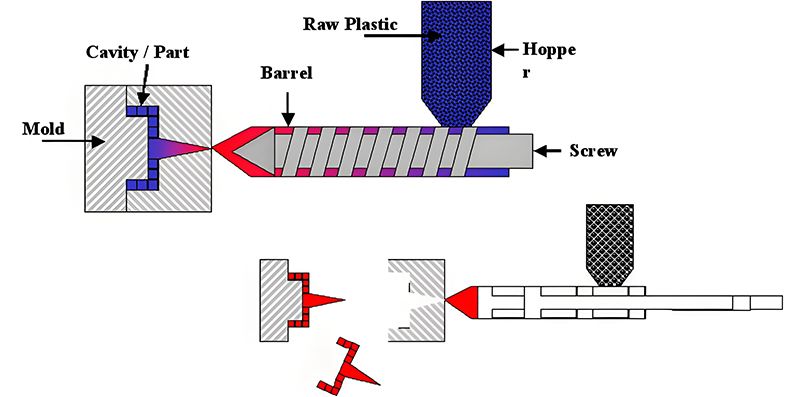

Injection molding is a processing method that uses an injection machine to inject heated and melted materials into a mold, and then cools and solidifies them to obtain finished products. Injection molding has a wide range of processing, including various types of materials such as plastics, metals, and glass. Specifically, the scope of injection molding processing includes but is not limited to the following:

1. Plastic injection molding

Plastic injection molding is the most widely used method in injection molding processing. It is suitable for various types of plastics, such as polypropylene, ethyl polyacrylate, polycarbonate, etc. It can produce plastic parts of various shapes and is widely used in fields such as automotive parts and electronic products.

2. Metal injection molding

Metal injection molding is a method of manufacturing metal parts using injection molding technology. It mixes metal powder with bonding agent, and then injects the mixture into the mold through an injection machine. After solidification, the finished metal parts are obtained. Metal injection molding is suitable for various metal materials, such as iron, copper, aluminum, etc., and is widely used in fields such as automotive manufacturing and 5G communication.

3. Glass injection molding

Glass injection molding is a method of producing glass products using injection molding processing methods. It mixes glass powder with bonding agents and other additives, and then injects the mixture into the mold through an injection machine. After solidification, the finished glass product is obtained. Glass injection molding is usually applied to high-precision glass products, such as optical lenses, LED packaging, etc.

In which fields are injection molding widely used

Due to its high efficiency, precision, and quality, injection molding is widely used in various industries and fields. The following are the applications of injection molding in some fields:

1. Automobile manufacturing

Injection molding is a widely used processing method in automotive manufacturing. It can produce various car parts with different shapes and materials, thereby improving the overall performance and quality of the car. For example: body shell, steering wheel, wheels, etc.

2. Electronic products

Injection molding is also widely used in the manufacturing process of electronic products, which can produce various electronic components with different shapes and materials. Injection molding processing can achieve high-precision and high-efficiency production effects, such as phone cases, TV frames, keyboards, etc.

3. Medical devices

Injection molding methods are also widely used in the production of medical devices. Injection molding can produce high-precision and high-quality medical device components, such as infusion sets, atomizers, syringes, etc.

In short, injection molding has a wide range of processing and application fields, and its high-quality and efficient processing methods will be increasingly recognized and applied in various industries and fields.

Thingyfy has an experienced international design team that can transform a customer's concept or idea into a product that can be produced. Through our existing processing and production team, we can achieve seamless integration of product samples, testing, small-scale production to large-scale production. We will implement your ideas and expectations one by one. Are you ready to start a new project?

HIGH QUALITY SERVICE

Thingyfy is committed to providing high-quality injection molding, die-casting, silicone processing products and molds.

We also provide mold processing services, with a variety of mold processing materials for you to choose from.

THINGYFY'S RAPID PROTOTYPING SOLUTION