Surface Finishing

Surface processing technology is a series of process methods used to treat and improve the surface quality and performance of workpieces. Common surface processing techniques include the following:

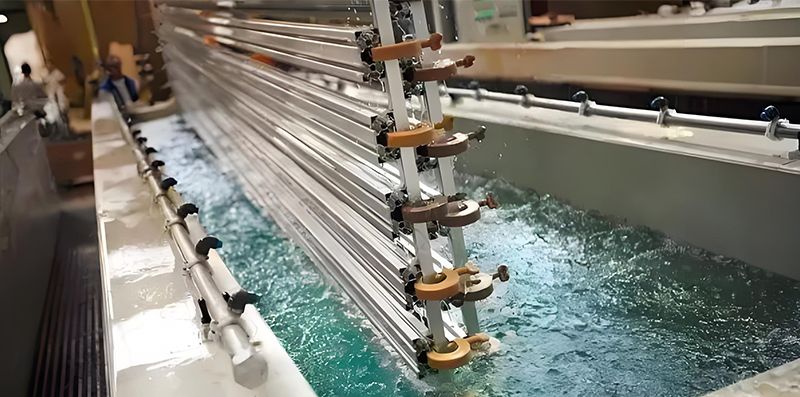

1. Water transfer printing: A printing technique that transfers patterns to the printed material through the pressure of water and an activator.

2. Metal wire drawing: Processing straight lines on aluminum plates or metal surfaces, with decorative and protective effects.

3. Etching: Creating patterns or text on the surface of a workpiece through chemical or physical methods.

4. Sandblasting: Use high-pressure sandblasting sand or iron shot to impact the surface of the workpiece, in order to strengthen the surface and change the surface condition.

5. Spray coating: The coating is evenly sprayed onto the metal surface using a spray gun or other tools to achieve specific properties such as conductivity, wear resistance, and thermal insulation.

6. Embossing: Use uneven molds to create patterns on metal surfaces, creating a relief like effect.

7. Polishing: Use polishing wheels to process the surface of the workpiece to eliminate residual fine grinding marks after polishing and obtain a bright appearance.

8. Electroplating: A layer of other metal is coated on the surface of the workpiece to improve conductivity, wear resistance, reflectivity, and corrosion resistance.

9. Anodizing: By electrolysis, a layer of oxide film is formed on the surface of the workpiece to improve its hardness and corrosion resistance.

10. Phosphating: Generate a layer of phosphate chemical conversion film on the metal surface to protect the metal from corrosion and improve the adhesion of the paint.

These process methods are widely used in various industries to improve the aesthetics, durability, and corrosion resistance of workpieces.

Thingyfy has an experienced international design team that can transform a customer's concept or idea into a product that can be produced. Through our existing processing and production team, we can achieve seamless integration of product samples, testing, small-scale production to large-scale production. We will implement your ideas and expectations one by one. Are you ready to start a new project?

HIGH QUALITY SERVICE

Thingyfy is committed to providing high-quality injection molding, die-casting, silicone processing products and molds.

We also provide mold processing services, with a variety of mold processing materials for you to choose from.

THINGYFY'S RAPID PROTOTYPING SOLUTION